Industrial Assessment Center

Save money. Work cleaner.

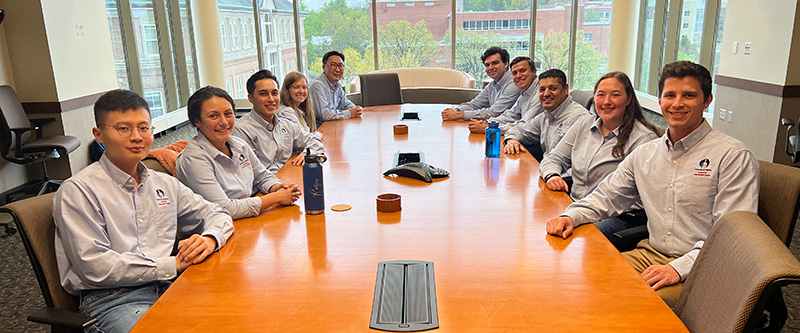

The UD-IAC provides no-charge energy assessments for regional industries. We have performed over 1000 industrial assessments. Our clients report saving an average of about 10-15% on their energy costs as a result of our assessments. Assessments are led by a faculty member and an experienced team of mechanical, industrial, chemical and environmental engineering graduate students.

Since 1978, the U.S. Department of Energy has sponsored a program to provide no-charge audits for companies like yours because many small- and medium-sized industries lack the in-house expertise to identify and implement the latest energy efficiency, pollution prevention and productivity measures. In today's competitive business environment, saving energy, reducing waste and improving productivity are more than just buzz words; they are vital to the success of every manufacturing firm.

In most cases, the IAC team will perform the assessment in a single day. Our approach is to work with plant personnel to identify savings opportunities. We will examine your utility bills, facilities, equipment, manufacturing processes and waste streams. Within six weeks an easy-to-read, confidential report will be delivered documenting current practices and recommending ways to save money by reducing energy and waste streams, and improving your manufacturing processes. The report is an independent assessment of your facility needs and is not biased by the desire to generate sales or consulting opportunities.

To qualify for a no-charge assessment, your plant must have a Standard Industrial Code between 2000-3999 (i.e. manufacturing/industrial) and annual energy bills between $100,000 and $2,500,000.

Phone Interview

- After agreeing on a convenient date and time for our plant visit, we ask a few questions about your process so that we may assemble the most appropriate audit team.

Pre-Assessment Information Packet

- We request a packet of information in advance of our visit. The packet typically includes: 1. Photocopies of the last one or two years of energy and water bills, 2. Photocopies of your electricity and water rate schedules (if necessary), 3. A list of waste streams with approximate quantities and disposal costs, 4. A schematic of the plant layout, 5. A map to the plant.

The Audit Team

- Our team typically consists of one or two faculty members and up to four students. The students are paid undergraduate and graduate workers from Mechanical, Environmental, Chemical and/or Industrial Engineering. Our team is completely insured, has industrial experience and has been briefed on plant safety issues. We will sign and honor confidentiality agreements and ask permission before taking any photographs.

The Day of the Audit

- We typically arrive about 9 a.m. and leave at about 4 p.m. Our plant visit usually consists of the following activities: 1. An introductory briefing, with management participation if possible. 2. A plant tour by someone familiar with plant equipment and processes. 3. A brainstorming session to generate savings opportunities. 4. Time for observations and measurements to quantify potential savings. 5. A short debriefing, with management participation if possible.

The Final Report

- Within six weeks, a complete, confidential report will be mailed to you. The report begins with a brief summary of our cost-saving recommendations and includes descriptions of utility data, process, facility, lighting, waste streams, and detailed descriptions of each recommendation showing all assumptions and methods used to generate the savings estimates.

Follow up

- We will contact you again in six to twelve months by phone to see which recommendations were implemented and to assess your overall satisfaction with our service.

Our Industrial Assessments are fully funded by the U.S. Department of Energy for medium-sized manufacturers. To qualify for a no-charge assessment, your plant must have

- Standard Industrial Code between 2000-3999 (i.e. manufacturing/industrial);

- Annual energy bills between $100,000 and $2,500,000;

- SIC Code Description 20xx Food and kindred products 21xx Tobacco products 22xx Textile mill products 23xx Apparel and other textile products 24xx Lumber and wood products 25xx Furniture and fixtures 26xx Paper and allied products 27xx Printing and publishing 28xx Chemicals and allied products 29xx Petroleum and coal products 30xx Rubber and misc. plastics products 31xx Leather and leather products 32xx Stone, clay, and glass products 33xx Primary metal industries 34xx Fabricated metal products 35xx Industrial machinery and equipment 36xx Electronic & other electric equipment 37xx Transportation equipment 38xx Instruments and related products 39xx Miscellaneous manufacturing industries SIC and NAICS Descriptions SIC (Standard Industrial Codes) SIC-NAICS Code Conversion.