Cold Spray Repair Technologies

Developing and implementing agile metal repair technologies

UDRI focuses on transformational technology areas to support and enhance technology readiness and enable cost effective engineering. UDRI continues to build up repair technologies to provide customers greater agility, improved speed of execution, and improved speed of technology transition to the field. All capabilities drive sustainment improvement and mission readiness.

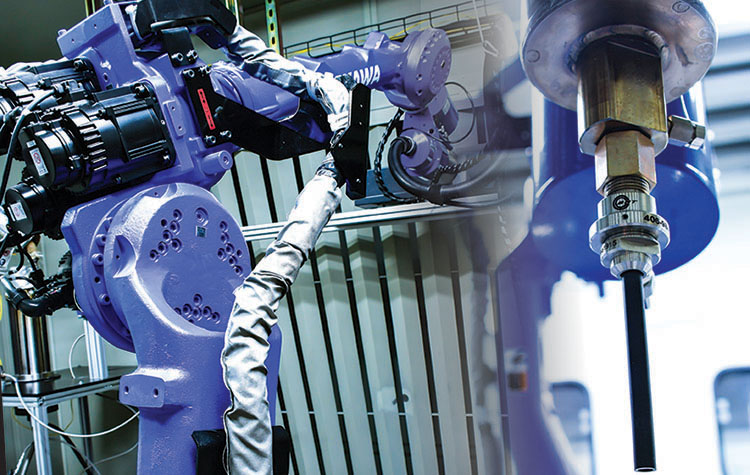

Cold spray is a surface repair via supersonic particle deposition of metallic powder to worn, damaged, or corroded substrates. Its advantages include the ability to repair and reuse valuable parts, reduce repair lead times, replace hazardous methods, and deposit wear resistant coatings. Cold spray is utilized for dimensional restoration of parts that are readiness critical and have long lead times for replacement.

Capabilities

- Materials Optimization - UDRI has experience in characterization of powder for multiple substrate/powder combinations creating optimized adhesion performance.

- Diagnostics - UDRI has the capability to observe the kinetic energy properties of a cold spray plume using laser diagnostic techniques.

- Scanning and Modeling - UDRI has the capability to perform reverse engineering of existing products via 3D digitization and geometric analysis, 3D printing of hardware and prototype models, and computer design and optimization of repairs.

Contact Us: 937-229-2113 | E-Mail | Form

Top: Low-pressure cold spray equipment for applying aluminum powders. Image credit: UDRI