Additive Manufacturing

Advanced Manufacturing Capabilities Video

AM Technology Development

UDRI designs, analyzes, builds, tests, transitions, integrates and sustains groundbreaking technologies in additive manufacturing.

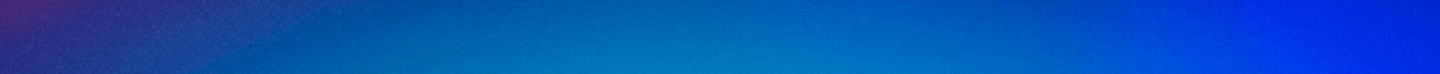

Learn MoreAM Quality Inspection

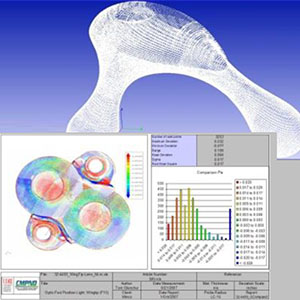

UDRI tests the effect of various materials and process variables; we also study process monitoring and the development of process control schemes.

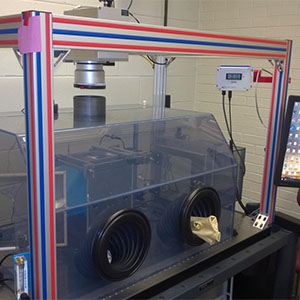

Learn MoreRepair with Additive Manufacturing

UDRI supports and enhances cold spray technologies to provide customers with sustainment improvement and mission readiness.

Learn MoreComplete solutions to increase profit and reduce waste

UDRI offers comprehensive capabilities and research services in additive manufacturing (AM), otherwise known as 3D printing, in which a computer-driven printer deposits layers of polymer, metal, or other media to create simple or intricate objects from a three-dimensional, digital design file.

With progress being made in AM, the technology can be used for new products, printing spare parts for system sustainment or creating various sized tooling and molds for traditional manufacturing. In the sustainment world, these parts, tooling, and molds do not yet exist or no longer exist and cannot be produced by any other means. In addition, AM can reduce lead times and can cost significantly less due to it being a tool-less operation.

Our scientists and engineers are conducting large-scale, high-level research and operations for multiple customers in both the commercial and government sectors. Contact us today and put our knowledge and experience to work for your organization.

Capabilities

- Advanced, Printable Composites - UDRI performs R&D in advanced, printable composites, specifically to help reduce the time and cost of manufacturing composite structures for aircraft.

- Repair with Additive Manufacturing - UDRI offers expertise in this solid state metal surface repair technology, allowing the repair of high-dollar assets in a fraction of the typical lead time and cost.

- Computer-Based Models - UDRI develops models that allow manufacturers to better predict the cost of developing a printed part, which can be difficult for small- and mid-sized businesses.

- Integration of AM into Production - Often manufacturers are unsure how to adopt and integrate additive manufacturing into their current processes. UDRI helps create a “recipe” including development and analysis of materials and sample parts, production trial runs and subsequent production, along with ISO-certified quality control.

- Manufacturing Tooling - Our researchers develop advanced additive manufacturing processes that produce complex geometry tools at a fraction of the cost of conventionally machined metal tools.

- Materials Optimization - UDRI has experience in characterizing powder for creating build parameters leading to optimized material performance.

- Printed Metals - UDRI has in depth experience in designing parts for AM, printing in a myriad of powders such as 17-4 stainless steel, titanium, aluminum, and nickel-based alloys, and developing innovative solutions to minimize residual stress.

- Printed Polymers - UDRI has the capability to print standard polymers such as ABS, nylon, and Ultem® (polyetherimide), as well as advanced polymers such as Antero and Carbon-Infused PEKK.

- Product Development - UDRI has the capability to perform new product design or reverse engineering of products via 3D digitization and geometric analysis, 3D printing of hardware and prototype models, and computer design and optimization of components, molds, and tools.

- Training - UDRI offers education and training to provide technicians and engineers with the tools and mindset to maximize the potential of AM and Cold Spray.