Kinetics and Process Engineering

Looking Towards a Cleaner, More Efficient Future

UDRI’s Kinetics and Process Engineering researchers investigate the interactions involved in and results produced by dynamic processes such as combustion; incineration; laser photolysis; soot and pollutant formation; algae formation, growth, and extraction; hypersonic flight; thermochemical, biochemical, and electrochemical conversion to energy. We explore and develop commercially viable technologies and methodologies that solve our clients' energy challenges.

Our customers include both commercial and governmental organizations, such 3M, DuPont, EPA, SPI (Society of Plastic Industry), and the US Air Force.

Capabilities

Using our specialized expertise, we perform work in the following areas:

- Fuel Desulfurization, both Hydrodesulfurization (HDS) and Oxidative Desulfurization (ODS). Our researchers have successfully achieved reduction of a sulfur concentration from 2000 ppm to fewer than 15 ppm using the ODS process.

- Aerothermodynamic studies to increase the fidelity of engineering models for thermochemical nonequilibrium using molecular simulation as a bridge between quantum chemistry and Computational Fluid Dynamics (CFD)

- Computational modeling for gas-solid and liquid-solid interface chemical reaction mechanisms and kinetics studies in order to better understand the interactions between fuel and fuel components such as tanks, lines, and seals

- Development of hydrogen technologies such as a high-efficiency electrolyzer and web-based techno-economic comparison tools for renewable energy storage

- CFD / flow simulation such as jet engine combustor flow in a small UAS, or particle flow from a nozzle

- Thermal degradation studies and incineration byproduct analysis through research using UDRI's System for Thermal Degradation Studies (STDS), consisting of a pyrolyzer, furnace, and in-line GC-MS

- Fluorotelomer thermal degradation studies to show how fluorotelomers (a type of coatings used in fire-fighting foams, grease-resistant food packaging, leather protectants and stain-resistant carpeting and textiles) degrade when exposed to heat

- Laser Assisted Chemical Depainting (LACD), a process used to strip paint from parts, compared to using chemical paint strippers alone

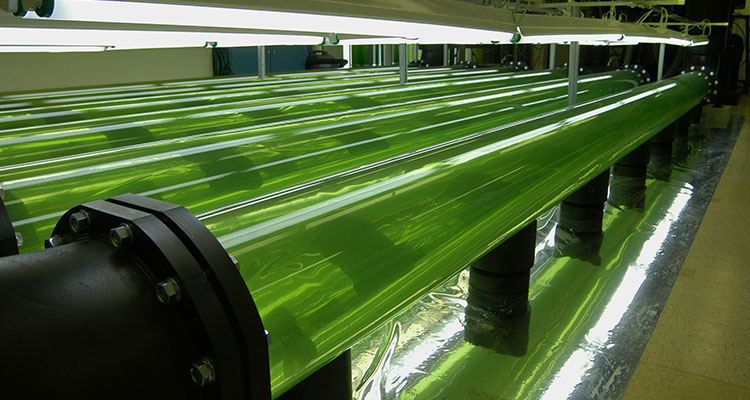

- Algae research to capture carbon dioxide and provide sustainable biofuel by investigating all the processes required for commercial viability

- Bioremediation of wastewater to remove heavy metals, pharmaceuticals, and various other industrial wastes from effluents

- Hydrothermal liquefaction / gasification of biomass or organic waste to extract useful nutrients and produce bio-crude oil

- Combustion research using shock tubes to provide fundamental data at relevant combustion conditions, develop / validate mechanism(s) over a wide range of conditions, and study fuel effects on ignition and emissions

- Continuous solid fuel combustion in a multi-fuel boiler to capture carbon dioxide, characterize emissions from multiple solid fuels, study oxyfuel combustion, and develop post-combustion product clean-up / after-treatment technologies

- Cone calorimeter studies to characterize trace-level emissions

Contact Us: 937-229-2113 | E-Mail | Form

Top: Studies underway at UDRI's Algae Research Lab