Advanced Composites, Modeling & Characterization

Understanding how Materials Behave

UDRI’s Advanced Composites researchers design, model, manufacture, develop processes, repair, and characterize advanced composites and hybrid materials. Focusing on aerospace and high performance applications, we conduct materials research and development to better understand the fundamental physics of the material’s response to external conditions.

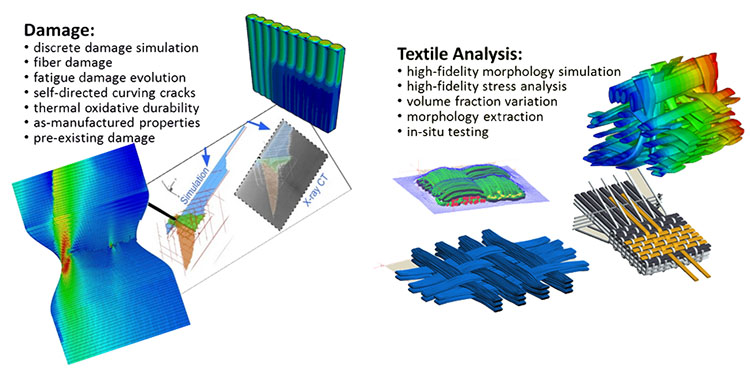

Current focus areas include use of UDRI-developed, high-fidelity finite element analysis (FEA) models, to design preforms with novel fiber architectures using tailored fiber placement technology. Companion technologies include development of additively manufactured thermoplastic composite tooling and rapid consolidation and cure.

Our work includes R&D with a wide range of adhesive, composite, plastic and core materials. We process and evaluate fiber-reinforced polymeric composite materials, adhesives and primers, cores, fabrics and textiles, and transparency and plastic materials.

Our highly versatile, ISO 9001:2015 registered Composites Manufacturing and Testing laboratory contains a wide array of equipment for processing and evaluating adhesives, primer, fiber-reinforced polymer matrix composites, nanocomposites, and plastic materials used in military and commercial applications. In the laboratory, our researchers perform both routine and specialized evaluations and material characterizations on composites, adhesives, sandwich constructions and plastics.

We determine material properties following their exposure to various environmental conditions and temperatures. We are fully equipped to process and machine all types of fiber-reinforced composite and bonded adhesive joint test coupons.

UDRI is a founding core member of the Institute for Advanced Composites Manufacturing Innovation (IACMI). UDRI’s role is to foster industry supply chain development and transition of new technologies serving the composites community.

Capabilities

- Manufacturing/Processing: Additive (AM), Autoclave, Presses, RapidClave, VARTM, Injection Molding

- Design: BSAM-FEA, Virtual Textile Morphology, Solidworks Design

- Preforming: Tailored Fiber Placement

- Composite Optimization: Suite of in-house tools for design of composite structures and devices

- Bonding and coating: Adhesive Bonding Technology, Nanocomposite Coating, EMI Shielding, Environmental Conditioning

- Agile Tooling: Atlas AM Printer

- Characterization/Testing: Thermal Analysis Lab, Mechanical Testing, Creaform Scanner Repair

Along with the above capabilities, we can perform composite lay-ups, processing, and specimen fabrication. We have extensive experience with all types of fibers, matrices, core materials, etc. With the combination of fabrication and testing, we can accomplish everything at a single location.

Contact Us: 937-229-2113 | E-Mail | Form

Top: FEA predictions for composite failure progression (left) and fiber architecture (right)