Nondestructive Evaluation

Nondestructive evaluation and mechanical testing

Our Nondestructive Evaluation (NDE) researchers provide expertise in development, enhancement, and integration of advanced NDE and characterization technologies for aerospace materials and their properties.

Capabilities

NDE

- Eddy current

- X-ray computed tomography

- Thermography

- Ultrasound/phased array

- Resonance methods

- Metallography/optical microscopy

- Surface profiling/roughness

Mechanical Testing

- Monotonic, fatigue, sustained loading

- Up to 1500⁰C

- Vacuum testing to 10-9 torr

- Thermal gradients

Integration Support

- Automation

- Systems development

- Statistical methods

- Machine learning

- Image/signal processing

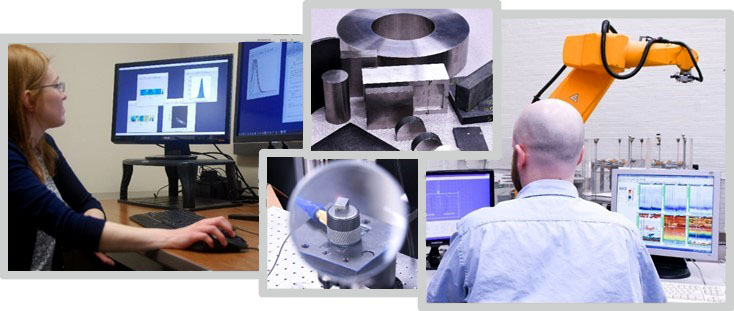

Our researchers bring expertise in materials characterization, processing, mechanical testing, and systems design to every application. In addition, our researchers have extensive experience in NDE-related areas including robotics and automation, statistical and inversion methods, image and signal processing, as well as modeling and simulations. Our perspective on NDE methods is particularly unique since our researchers and laboratory include state-of-the-art destructive characterization capabilities including mechanical testing (high temperature and vacuum) and metallographic capability that can be used to correlate NDI data with actual flaw parameters.

UDRI’s NDE Engineering experience in robotics and automation provides the capability to enhance existing experimental systems, as well as design the next generation of automated systems for laboratory, industrial or depot use. Our experience in image and signal processing includes a variety of data formats obtained from NDE sensors and imaging systems. This broad experience base provides our customers with a research team that can assist with identifying technological advances in optical imaging and sensor signal processing that are applicable for NDE sensing. Our experience in modeling and simulations of NDE measurements and related behavior provides a research team that understands the benefits and limitations provided by model-based experimentation, as well as how experiments can be best used to validate model predictions. UDRI’s experience with statistical methods ensures that our NDE research focuses on quantitative outputs and imparts confidence in those results. All of these supporting areas of expertise provide an NDE solution that is flexible and responsive to future NDE needs and innovation requirements.

Contact Us: 937-229-2113 | E-Mail | Form

Top: NDE encompasses many sensor modalities and engineering capabilities. We combine experience and experimental capability to optimize for each application using models and simulations to support experimental design, to better understand signal/material interactions, and to create test specimens that represent fielded components and anticipated flaws. By incorporating automation throughout the inspection process, we increase NDE reliability, repeatability, and throughput and reduce cost.