Structural Engineering

Pioneering Ways to Solve Challenging Problems

For over 30 years, UDRI Structures researchers have solved complex engineering problems and conducted structures-related research and development. We approach and address unusual and challenging structural engineering problems by combining existing analysis and testing technology, developing computational and experimental techniques, and cultivating new materials and manufacturing methods. We apply computational mechanics (especially finite element analysis), combining the principles of engineering mechanics with approximation techniques and numerical methods, to solve complex stress, thermal, impact, vibration, and other structural problems.

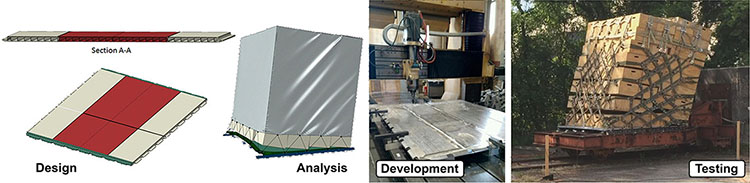

UDRI has significant experience working with aircraft subsystems such as airframe structures, transparency systems, landing gear, tires, radome structures, and engine components. Our engineers have designed or redesigned, analyzed, tested, and qualified numerous parts now flying on military and commercial aircraft. We have experience with hypersonic vehicle structures, structural health monitoring, wind tunnel model development, automotive components, manufacturing equipment, hospital and medical equipment, bicycles, personal watercraft, military transport vehicles, shipping containers, military shelters, aircraft ground support equipment, and more—such as the Next-Gen all-aluminum extruded friction stir-welded 463L cargo pallet design shown above.

Contact Us: 937-229-2113 | E-Mail | Form

Top: Illustrated phases of UDRI's work to develop the Next Gen Cargo Pallet for the US Air Force.