Laser Manufacturing Technology Development

Advanced laser manufacturing solutions specializing in ultrashort pulsed laser (USPL) systems

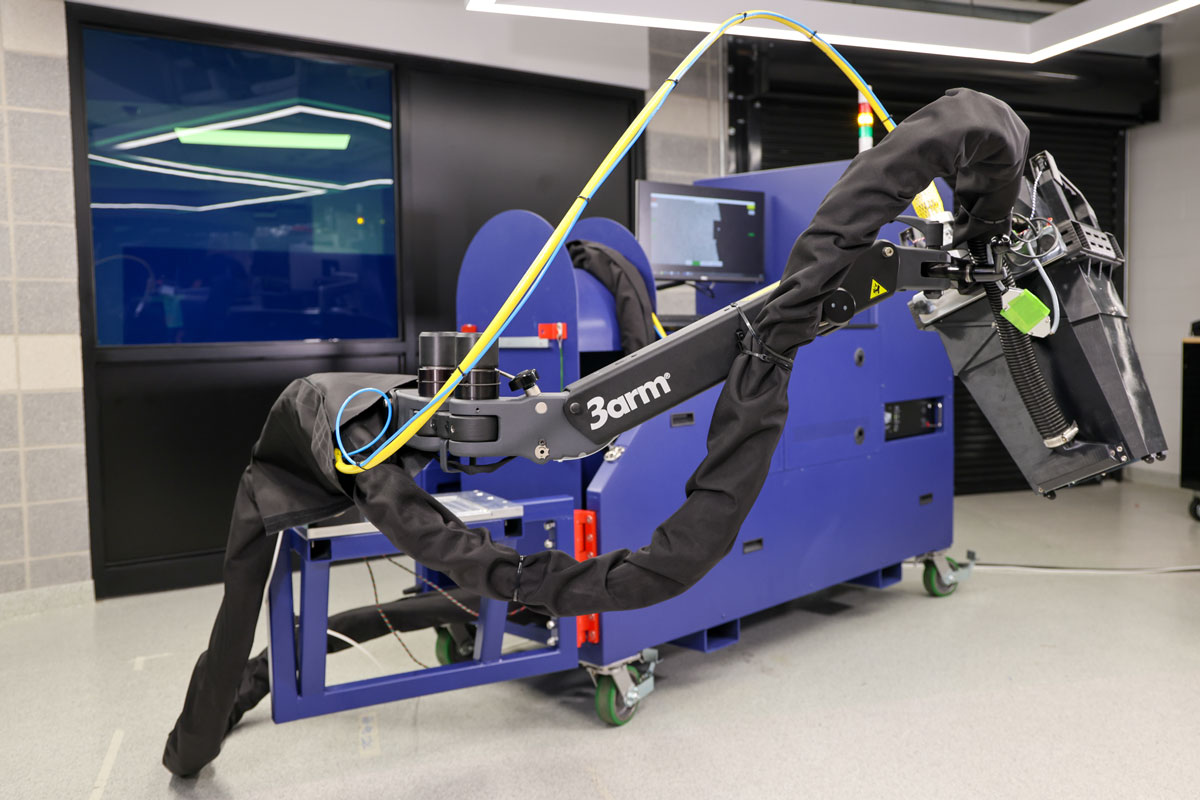

UDRI’s Laser Manufacturing Technology Development experts provide applications research and development for both US government and industrial sponsors. We are the lead developers of the award-winning Composite Laser Ablative Surface Preperation (CLASP) process, and specialize in creating Ultrashort Pulsed Laser (USPL) systems and processes to help solve current manufacturing challenges.

We have multiple researchers with over a decade of USPL applications and system development expertise and we have developed laser applications in most material families, including metallics, ceramics, polymers, composites, coatings, and more.

Our facilities are equipped with several custom laser workstations, with both fiber-coupled and open-beam train configurations and motion systems ranging from simple XYZ gantry to 5-axis robotic arm integrations. Our researchers also collaborate with laser equipment manufacturers to field test equipment under development, with the goal of improving the capabilities of the USPL industry.

Our customers include US government organizations, primarily the U.S. Air Force and Air Force Research Laboratory (AFRL), as well as aerospace equipment manufacturers. The team also works with a variety of industrial customers across various fields to investigate laser material applications of need.

Capabilities

- Laser Applications development

- Custom laser system development

- Laser system beta testing

- Laser applications sensor development

- 5-axis micro-machining

- IR/Green/UV femtosecond laser applications

- Athermal laser material processing

Top: UDRI designed and developed Composite Laser Ablative Surface Preperation (CLASP) system